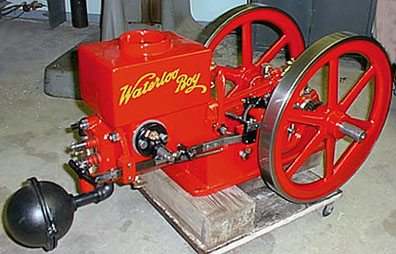

The Waterloo Boy Restoration Project

Phase 7 – Feb. 15, ’98 to Mar. 6, ’98

The painted connecting rod is now assembled with the piston and wrist pin. The pin is locked in place by two square head screws and jam nuts. The piston rings have also been installed on the piston.

After the piston/rod assembly is installed in the cylinder, the new shims are placed on the main bearing studs and the crankshaft is laid into the block. The main bearing caps will then be installed and tightened with a final check for fit being done. With grease in the bearings, the crank should be able to be turned by hand with some slight effort.

Once the connecting rod has been attached to the crankshaft, the smaller valve train items can be installed. First, the governor mounting bracket is loosely attached and the cam gear pin is also installed. After the governor itself is assembled, it is installed in the bracket and secured with the governor gear (not shown). The cam gear is temporarily installed and meshed with the governor. With proper meshing of the gears, the mounting bracket can now be bolted down tight. The cam is once again removed to allow further assembly of the valve train.

At this point, the only remaining restoration work to be done is on the flywheels. Since the use of a friction drive ‘Motsinger Auto-Sparker’ for the ignition is planned for this engine, the flywheel rims need to cleaned up to provide a smooth surface. To accomplish this, both flywheels are turned in the lathe and a skim cut is taken off of the face of the rims. This also improves the looks as the clean cast iron will be painted clear to preserve the raw metal. These 18″ wheels are about all my lathe will handle!

With the remaining valve train, ignitor, assembled cylinder head, muffler, and brass grease cups and oiler installed, the engine now is starting to resemble it’s final look. An interesting note here: it was on this date 87 years ago today (Feb. 21) that this engine was originally assembled by the factory and shipped.

The restoration of the 1911 Waterloo Boy is now complete, as far as the engine itself. Reproduction cart parts are now in the shop ready to be cleaned up and painted, along with wood rails that need to be cut, fitted and finished. Also, a gas tank and coil box have yet to be designed and built. The fun continues….

Next