The Waterloo Boy Restoration Project

Phase 2 - Dec. 2, '97 to Dec. 14, '97

This engine is one of the more rudely finished engines I’ve encountered. The patterns used when casting the block where not only badly misaligned with each other, but the actual pour of the cast iron was both cold and quick. I still have to wonder how Waterloo was ever able to machine this particular block! Shown here, for future machining purposes, the stripped block was put into the mill and a cleaning cut was taken across the bottom to provide a straight reference point for other operations. In some spots, nearly a 1/4 of an inch was removed while still leaving plenty of ‘meat’ on the base.

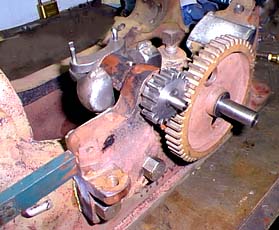

Once the block was machined to sit flat in the mill, the cam gear pin mounting hole was re-bored square with the cylinder bore. Originally, the cam gear had a very noticeable upward cant that had somewhat worn the gear teeth. The cam gear itself was reamed to get a straight and round bearing area, and finally a new pin was then machined to match the block and cam.

The mostly overhauled cam and governor assembly. The push rod will also need replacing, as the cam follower and pin wore the rod badly. The cam gear was originally held in place by the hub of the left flywheel. This engine had apparently been neglected, allowing it to become loose enough to allow the cam gear to start riding up onto the flywheel hub. This wore the edge of the cam gear teeth off and also cut into the hub. This restoration will result in the cam gear being pinned in place by a cotter pin.

The original push rod had two problems; a loose pin hole for the cam follower and the valve clearance adjustment stud was broken off. It was simply easier to make a fresh, new push rod than fight with the old one which was also bent and badly pitted.

With the new ‘repro’ ignitor and near completed push rod installed, things are looking up. The next real challenge will be the fabrication of the ignitor trip assembly.