The Waterloo Boy Restoration Project

Phase 6 – Jan. 29, ’98 to Feb. 14, ’98

The last major hurdle of the mechanical part of the restoration: Pouring the babbitt for the connecting rod bearing. Very much like the procedure for the main bearings, the rod and cap castings are first cleaned and prepared with molds to form the new bearing halves. For this engine, the bearing ends are flush with the outer edges of the rod, so a simple flat surface is used for a mold to contain the molten babbitt during the pour. Some designs use a protruding lip of babbitt as part of a thrust bearing surface. Waterloo has this thrust area within the rod dimensions.

Again, as with the main bearings, the newly poured babbitt is machined flat with the rod and the cap in order for the two to be bolted together with a new set of shims (thin sheets of metal only a few thousandths of an inch thick) in between. These shims allow for future adjustment of the bearing as it wears with use.

With the rod and cap assembled with the shims, the complete unit is shown mounted in the mill. A special mount was made to bolt onto the mill table and hold the rod square. The center of the new bearing is located by indicating off of the rod itself. Now the actual boring of the bearing can be done.

The babbitt is bored out to within just a couple of thousandths of an inch of the size of the crankshaft journal. Also, a radius or thrust bearing area is machined into the ends of the bearing (not shown) to hold the rod centered on the crankshaft.

The piston, rod and crankshaft, rough assembled. Also shown is the timing gear. Note the length of the rod (13.5″ / 34.3 cm) center of the wrist pin to center of the journal. This engine also still has the original two ring piston. According to the Waterloo parts manual, the original owners of these engines were instructed to order a ‘new’ three ring piston when they were in need of ordering new piston rings.

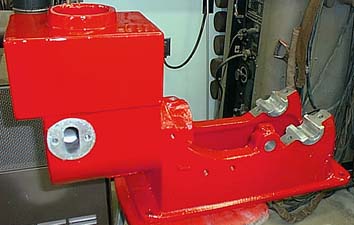

Well, you wanted red, you got red! The block finally gets it’s coat of paint and the project is really getting close to completion now. All the small parts are also painted, some red, some black, though early Waterloos were originally all red. The flywheels are now the only parts yet to be preped and painted.